We recommend using 2 stages for an efficient selection of the right product candidate(s).

Stage 1: Get a shorter list of the candidate products

There are 2 ways to get a shorter list:

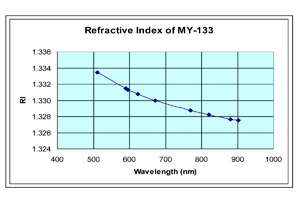

1. Define a limited range of relevant refractive index: Go to the PRODUCTS by REFRACTIVE INDEX page. Use the 2 red sliders to define the range of interest. You can move the sliders and see the list of products in the table, which becomes shorter or longer, depending on how you move the sliders. We recommend you select a range a bit wider than the range you actually need.

2. Alternatively, you may select a relevant category of products: Go to the PRODUCTS by CATEGORY page and select the category which seems most relevant. You’ll get a shorter list of products. At this point you may use the red sliders, to focus on a more limited range of the refractive index.

Stage 2: Focus on the best product candidate(s):

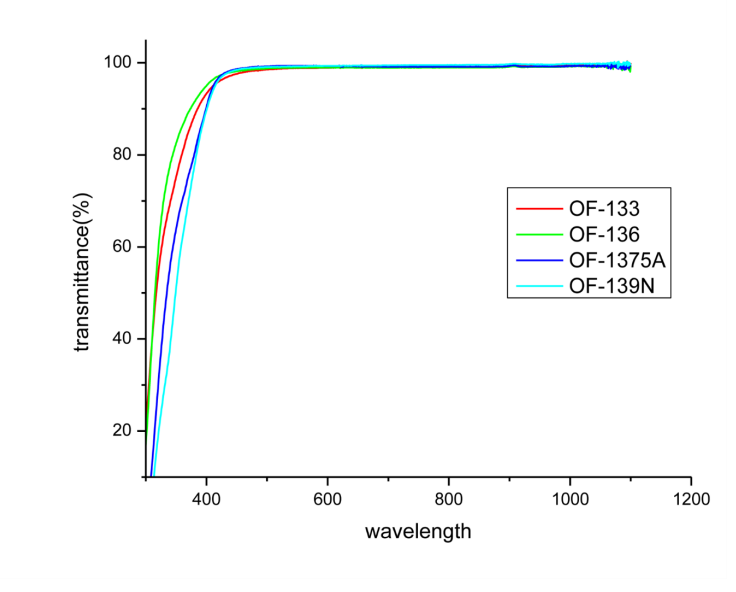

Now, that you got a shorter list of products, use the properties listed on the table to guide you in your final selection. Note that the columns include the most important properties: Refractive index (cured state, at both 589 nm and 950 nm), adhesion, modulus, tensile strength, viscosity (in the liquid state, before curing), Curing method, Hardness, and shelf life.

Once you get one or more candidates, you can download the datasheet. Click either the product name (left-hand column) or the right-hand column, marked as a PDF file. The datasheet includes many more details on each product.

Send us a message if you have any technical questions, and we’ll do our best to help in selecting the right product, and answering any questions.

Few tips when selecting products:

The lowest-index adhesives have inferior mechanical properties.

Typically, the lowest index products tend to have inferior mechanical properties (modulus, hardness, tensile strength), compared to higher modulus products. When selecting a low-index material we recommend you look at the modulus as a representative mechanical property.

Adhesion and our adhesion primers:

Excluding some notable exceptions, the lowest index materials also tend to have lower adhesion. (You can see this in the products table).

When important, you may consider using one of our adhesion primers. As this may complicate the production process, consider selecting an Enhanced Adhesion product.

For example, if you need an index of 1.33 AND good adhesion, MY-133-EA with an adhesion of 27 gr/cm should be preferred over MY-133-V2000 with only 9 gr/cm. (However, MY-133-EA has a shorter shelf life, and lower modulus, compared to MY-133-V2000).

Non-UV cured products:

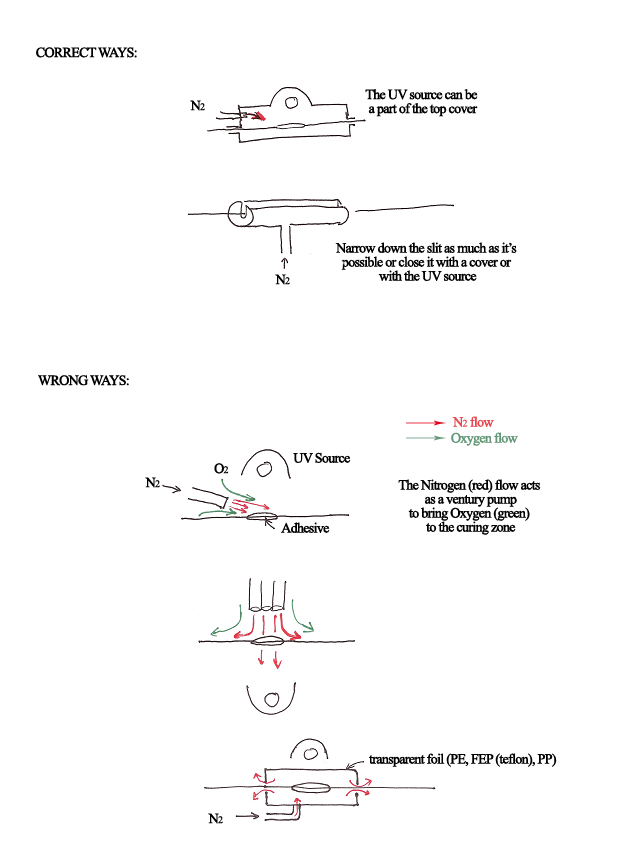

The vast majority of our products are UV cured, but we also have a few moisture-cured, dual-cured (UV or Heat), and pressure-sensitive products.

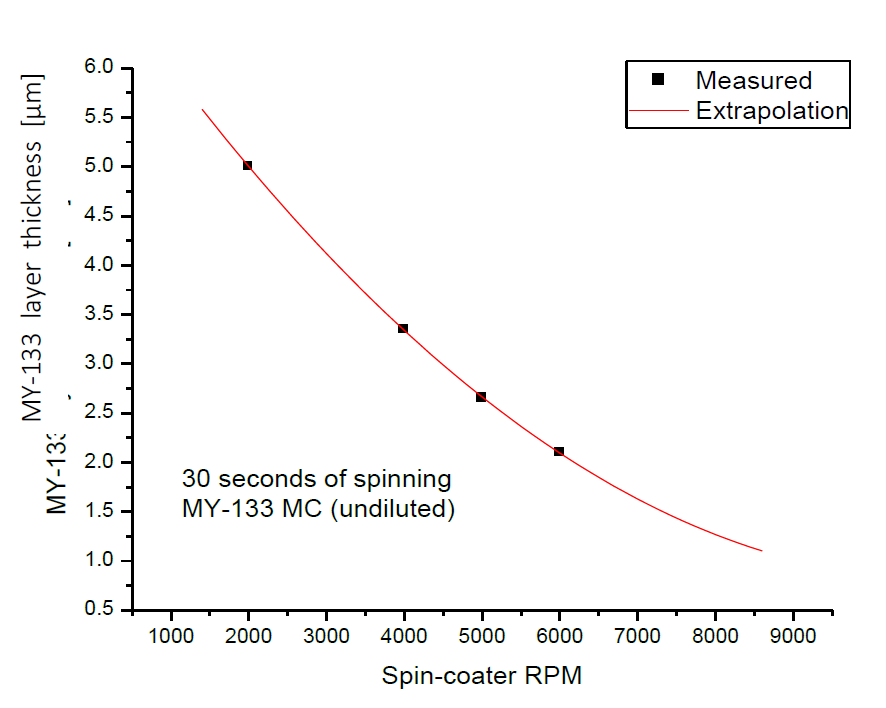

The moisture-cured (-MC, -AR) products:

The moisture-cured products do not need UV curing (and no inert atmosphere) for curing. Their typical use is as coatings. The MC/AR product are harder and have better adhesion compared to UV products with the same index. For example, MY-133-MC is harder and has better adhesion than MY-133-V2000; and AR-138 is much harder than MY-138.

The Double Cured (DC) products:

Double-cured products are used when a part of the area to be UV cured (or all of it) is shaded.

Pressure-sensitive products:

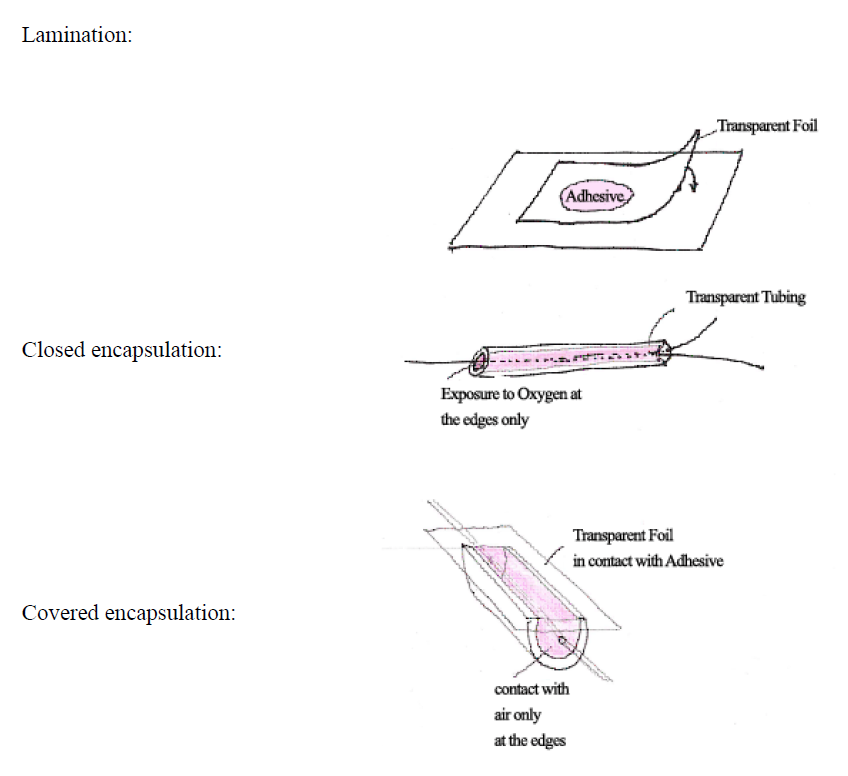

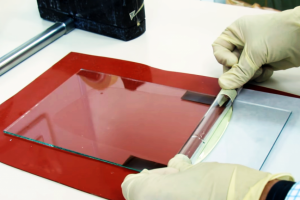

Pressure-sensitive products are an exception, combining both low indexes (1.33) and very strong adhesion. These are lamination adhesives. They are typically used to laminate films and flat substrates (e.g. in the electronic display industry).

Get us involved in the selection process:

Let us know if we can help!

Send us a message through the website, or send us an email to [email protected]. We try to respond quickly.

You can get us involved at any stage of the selection process, either beginning from scratch, after Stage 1, or after Stage 2.

Even if the selection process is done in the best way, many times it is not possible to zero in on only one single product. Quite often, not all the requirements are well defined. Therefore, it is typical for many first-time customers to focus on 2,3 or even more product candidates, order them, and run their own testing with their own specific target device to determine the final chosen product.